Alcon’s war on waste

Alcon is cutting back on packaging material manufacturing and reducing waste going to landfills with five significant initiatives across its New Zealand surgical and vision care portfolios.

Given Alcon’s large footprint in this market (about 80% of the cataract surgery market share), efforts to reduce waste are going to have a significant impact, said Jennifer Cole, newly appointed commercial head of surgical for Alcon New Zealand, who’s driving the local fight against waste.

The first key initiative is removing the plastic trays from Alcon’s Centurion Fluidics Management System (FMS) when included in Alcon Custom-Paks. “Working with facilities using Centurion and Alcon Custom-Paks, we’ve been able to reduce the number of Centurion FMS plastic trays manufactured and delivered to New Zealand by about 75%,” Cole said. Previously, the Centurion FMS were packaged in rigid plastic trays inside the sterile pack, meaning the facility would need to dispose or recycle the tray once used, she said. “Now, Centurion FMS are packaged inside the blue, sterile sheet without the bulky plastic tray, with all the contents inside ready for the scrub team to use. The facility no longer has to dispose of or recycle the plastic tray once the surgical list is complete, it is simply not there! The change has meant a reduction in carbon footprint by elimination of dual sterilisation and reduced transport costs, as the packs are lighter, while also reducing material waste and waste to landfill.”

Alcon has also eliminated the plastic overwrap on intraocular lens (IOL) cartons, saving 1.92g of plastic per carton by replacing it with a sticker seal, and removed the dense paper ‘directions for use’ booklet, replacing it with a QR code card. Plus, it’s created smaller, lighter packaging for newer IOL products such as Clareon, said Cole.

Alcon has also expanded its partnership with Plastic Bank, to offset all plastics generated by its contact lens division, to include its surgical products too. For each ton of plastic introduced into the marketplace by Alcon, Plastic Bank will collect an equivalent amount of ocean-bound plastic in vulnerable coastal communities. For Australia and New Zealand, Alcon estimates it will support the removal of plastic waste equivalent to 4.9 million plastic bottles this year, said Cole.

Another local initiative is ensuring IOLs aren’t sitting on shelves for too long, she said. “We are working closely with our customers to make sure they have the right lens on the shelf for surgery and looking at ways to manage inventory more efficiently. There’s an opportunity for us to review what’s actually being used and bring back what isn’t to our centralised warehouse. Then we can carry less stock, everyone has what they need and fewer products go to waste.”

Next, Alcon is looking to tackle the preloaded IOL injectors and BSS (balanced salt solution) bags used during phacoemulsification on the Centurion, Constellation and Unity VCS/CS, Cole said. “If we keep pushing the scope on what's possible, we'll find new things to do. I also believe there's an appetite from some of our larger customers to work together to help them set up recycling schemes and similar things.”

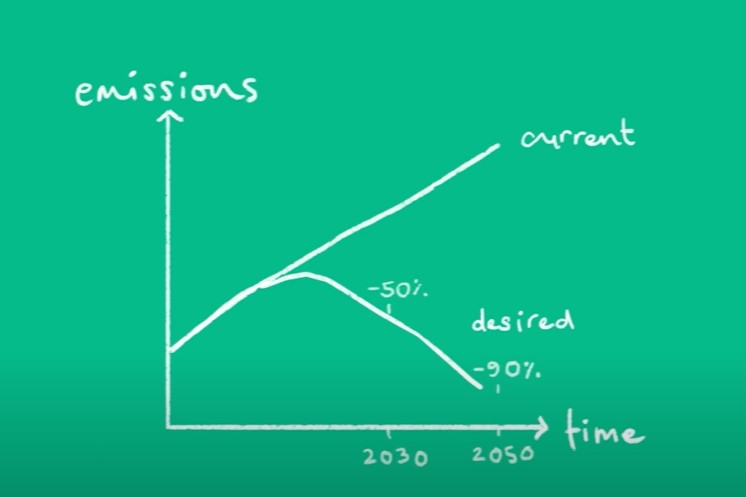

Operational waste reduction is one of four pillars in Alcon’s global environmental sustainability strategy and the company is committed to a rapid increase in landfill diversion and the number of zero-waste-to-landfill sites across the globe. Alcon’s 2030 goal is to become carbon neutral across global operations and to divert all non-hazardous manufacturing and distribution waste from landfill, said Cole.

“Ultimately, I’m super proud of what Alcon has done in a relatively short space of time to turn around our sustainability initiatives and focus, making it a real priority. On a personal level, I've got two young boys and I don't want to leave them a planet that's burning, so I’m pleased to be part of a company that is doing important work in this space. But there’s absolutely more work to be done!”