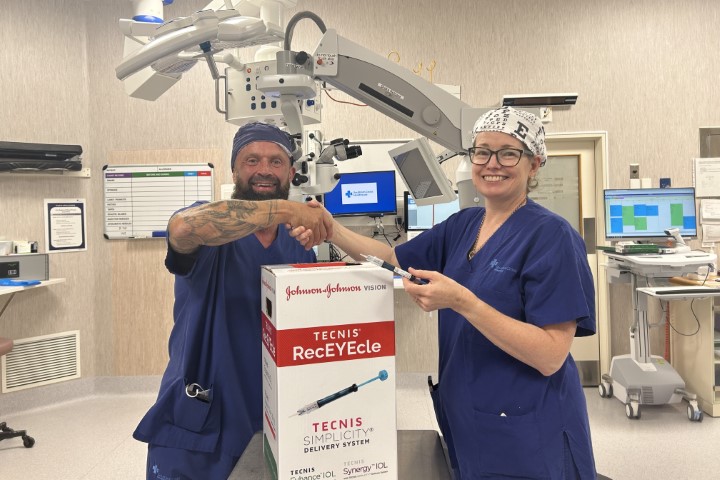

Innovative cataract-waste recycling scheme launched

A pioneering Johnson & Johnson (J&J) Vision initiative to recycle its plastic cataract surgery waste is being rolled out across New Zealand.

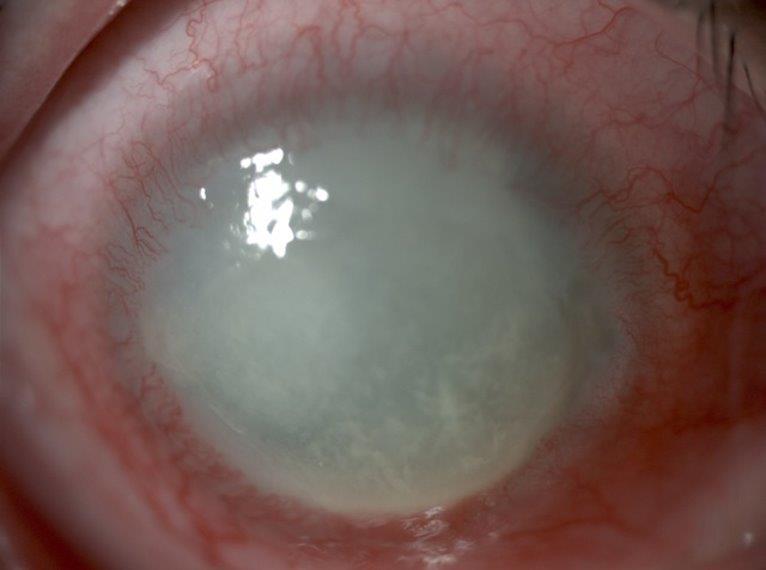

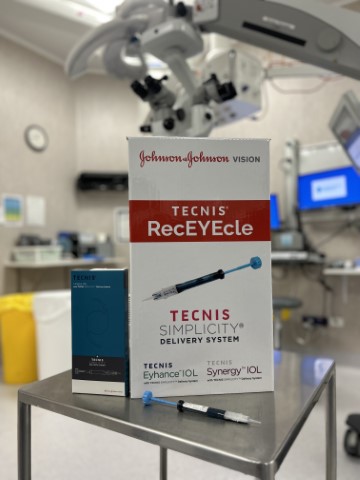

Under the company’s new RecEYEcle programme, J&J’s Tecnis Simplicity intraocular lens (IOL) loaders can now be disposed of in a specially designed and supplied box in ophthalmic surgical suites. Previously destined for medical landfill, as they come into contact with patients’ eyes, the Tecnis loaders can now be sterilised and the different plastic components shredded to make decking, bench seating and watering cans.

Mark Shephard, J&J Vision’s sales representative in South Island, said the idea was sparked by a series of coincidences, starting with the Royal Australian and New Zealand College of Ophthalmologists’ (RANZCO’s) sustainability charter and an article featuring Wellington-based Dr Jesse Gale discussing the burden of cataract surgery on the environment. Shephard then met with Southern Cross-affiliated Christchurch-based ophthalmologists Dr Ainsley Morris and Dr Elizabeth Conner. “They told me sustainability is very important to them, to the point where they try to reduce patient visits to cut CO2 emissions,” he said. “Then, when I got home there was a copy of NZ Optics in my letterbox, containing an article on sustainability!” The seeds sown, Shephard said he looked at the Tecnis loader and thought, “this is just plastic, why aren’t we recycling it?”

Boxing clever

After devising a recycling process, Shephard recruited a handful of New Zealand theatres to collect their used loaders in dedicated, lined bins to test and refine his model.

A RecEYEcle bin

“Once it’s two-thirds full, the RecEYEcle bin is collected by Interwaste as part of the scheduled collection, meaning no special trip is needed, further reducing the carbon footprint,” said Dr Morris, estimating she now uses one RecEYEcle box per month. The innovative programme has also reduced sharps disposal, which costs around 10 times more than using Interwaste, she said. “Mark has worked really hard to find a way to sterilise (the loader) so that the plastic component can be recycled. That was his idea and he's done all of the work.” Dr Morris also paid tribute to Wasana Burgess a member of Southern Cross’ Christchurch sustainability committee and ophthalmology clinical lead, who she said was instrumental in helping the recycling scheme come to fruition.

Asked whether J&J will accept other brands’ surgical disposables in its boxes, Shephard said while it is theoretically possible, the box is only for J&J single-use loaders at the moment. However, practices can recycle phaco packs used on the Whitestar Signature Pro or the new Veritas phaco machines by arrangement with their rep, he said. “Other items need clarification on the types of plastics contained and any other constituents. In the Simplicity loader, for example, there is a latex o-ring and in the phaco packs there is a metal component, both of which have to be removed.” The autoclave (steam steriliser) process has only really been tested on the inserter, added Dr Morris, while other surgeries may have more tissue contamination and therefore be more difficult to process.

Leading RANZCO’s sustainability efforts, Dr Gale said J&J’s RecEYEcle scheme was an exciting first in the recycling of medical waste to produce useful materials from what was previously landfill. “Although I'm still into finding solutions with the least single-use plastic possible, this is an impressive achievement as Mark navigated a lot of regulatory hurdles and found an innovative solution.”

Of the medical waste produced annually in US healthcare facilities, 1.7 million tonnes is plastic, according to a 2021 paper by Joseph et al.“If (the RecEYEcle programme) can be beta tested in little old New Zealand then sent to the US, it would be absolutely brilliant,” said Dr Morris.